Best Air Compressor Categories Introduction

In recent years the company are making so many air compressor categories. If you want to buy an air compressor then you must need to check all the categories.

I will discuss all the air compressors categories right here right now. So stay with me.

The main air compressor categories are

- General Air Compressor Category

- Quiet Air Compressor Category

I am going to discuss the two categories very well.

General Air Compressor

The Air compressors that we are using in our everyday life we called that type of air compressors are general air compressors. You will find many kinds of general air compressors out there. Let’s discuss them.

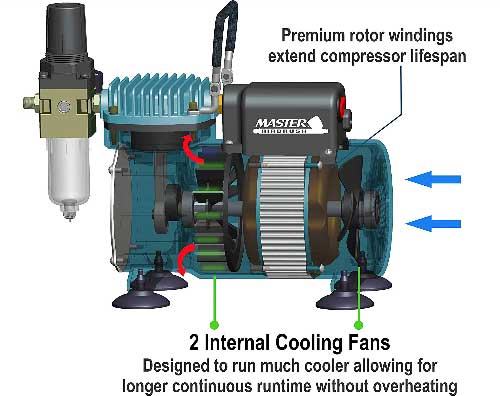

1. Air Brush Compressor

- Overall Description

Airbrushing is a new form of art. The artist’s canvass is an automobile or other such non-traditional source. This type of art is only made possible by using the power and efficiency of an airbrush compressor.

For most airbrush projects, the size of the compressor is not important. A small version air compressor should work fine. No need for an industrial-grade or commercial application type compressor. The more important piece will be the airbrush used.

Before running out to your local hardware store, determine first the necessary type. If you are beginning in the business, it may be a good idea to buy an airbrush kit. These kits will come with all your necessary components, tools, and materials, and the air compressor. The package-based upon the application, such as an automobile or even cake decorating.

Try online stores first for a wide selection of these kits, or check out a local hobby store or equal. An art supply store can also sell you the more advanced kits, be certain you know what you need. Once your business is established, there may not be a need for all the items in a kit.

At that time, it would be best to start getting more familiar with individual pieces. Take caution in that often, purchasing airbrushing pieces will be more expensive.

2. Portable Air Compressors

- Overall Description

Portable air compressors mean something different, pending the application. In an industrial or commercial setting, the application and use are different from use at home or traveling with an RV.

For a moment, let us focus on the use of a portable air compressor for traveling. If you wait until you are on your travels before checking air pressure, or should the ride start to change during your trip. There are not too many options when traveling in an RV as most gas stations will not have a convenient place.

Another thought to consider is that once your tires are in motion. They will heat up, providing you with an inaccurate reading anyhow.

Here is where a good, portable air compressor would come in mighty handy. The true application for such machines. But buying such a compressor may be more difficult than anticipated. As they come in a variety of flavors, with different bells and whistles.

The basics of all compressors come with standard ratings for horsepower, PSI, and CFM (cubic feet per minute). Once you understand these ratings, you will be able to make a more, well-informed buy decision.

Let us take, for starters, horsepower. Now, as it is in purchasing a car, you would assume the higher HP ratings to provide you with more horsepower, right? It would only seem logical that a four HP compressor would provide stronger, faster pressure than a two HP unit. But, that is not always the case.

Though it may not be false advertising unless you are in a commercial setting. You will not achieve anything close to the rated 4 HP. To understand this, let us examine what HP is? The term and use of horsepower were invented and coined by James Watt. Watts is used in measuring electrical and mechanical power and if we apply watts to HP, basic Watt principles tell us that one HP equals 746 watts.

In our example then, if you were plugging in your four HP compressor into a standard 120-volt source. You would only be able to produce shy of 2.5 HP, as the 120-volt source has a typical fifteen AMP service. In short, voltage x AMPS = watts (120 x 15 = 1,800 watts). If we divide that by 746, we get approximately 2.41 HP.

Though the PSI rating is not always inaccurate, you must first determine if the compressor can produce the PSI necessary, based on the true CFM. Once again, it may be possible that the compressor can produce such a PSI rating, but only if the CFM can achieve it.

CFM is the measurement of air produced by the rate of compressions. You are encouraged to determine your atmospheric pressure. As the CFM changes, based on that measurement, and also by temperature and humidity levels in the air. For note, the standard CFM calculated at sea level, 68 degrees Fahrenheit and with a relative humidity of thirty-six degrees.

So watch the rating of CFM by manufacturers. As if the rating is X PSI, but takes a CFM rating that cannot achieve in your environment. Then you will never get the pressure rated. This is important if you live in higher elevations, or northern climate where the air is heavier, or plan to travel to such areas.

3. Sullair Compressor

- Overall Description

Sullair is best known for its compressors used in medical applications. Such as their reciprocating air compressors used in dental applications. Surprisingly enough, air compressors are one of the most used machines in the medical field.

When you think air compressors, the thought of commercial or industrial situations come to mind, operating in workshops, and on construction sites. But, from dentist offices to operating tables, you will find air compressors in great use. They are an important aspect of not only making your smile whiter and healthier but assist in saving lives in your local hospitals.

Sullair is one of the top brands associated with such applications. They are made to be lightweight and very portable. There are many applications for using small reciprocating air compressors. Think about not only in dental situations or life-saving applications. Think also about the compressor that helps pump the needed oxygen into a child’s lungs to help him or her breath better, in the form of small nebulizers.

There used in first response situations, as oxygen pumped through a mask in an ambulance. Medical air compressors are necessary for life-saving situations.

Sullair also makes compressors for use in everyday kitchen appliances. From encapsulated to oil-free compressors, Sullair has something for almost any application or use.

Quiet Air Compressors

1. Screw Compressor

- Overall Description

Screw compressors, usually placed in the quiet air compressor category. Or known as rotary screw air compressors. They are designed to handle a wide range of dry material transfer applications. The basic operation of a screw compressor consists of two screw rotors, placed into action by gas compression.

These two screws, male and female, operate in the reverse direction, with the male rotor powering the female rotor. There are two types of rotary screw compressors. One is oil-free where there is a thin film of oil between. Then there is a dry version, in which a set of timing gears is used to help flow the screws.

Beyond the basic operation of the two screws, there are other, familiar operations to any machine. The container splits into a filled cavity and a discharge cavity. Whereby gas compresses into the discharge port, forcing the air to operate, or turn, the screws.

Once the rotation of the screw rotors decreases, known as the admissions phase, the exhaust phase comes into action. In which the rotors have completed their cycle and the gas discharged.

Though they are not known for the highest of pressures. They are much quieter than other compressors and have an extreme reliability rating due to their style of operation. Those make them ideal in several applications. Such as hydraulic power systems, stationery, and electric motor, and mobile applications.

2. Rotary Screw Air Compressor

- Overall Description

The rotary screw air compressor is one of two main categories in the air compressor industry. With the other being reciprocating piston compressors. The rotary screw, also known as a helical rotary compressor. It does not use values, instead, it uses positive displacement pumps to generate flow by applying an expanding cavity on the suction side of the compressor and a decreasing cavity on the discharge side.

The rotary screw compressor is usually deemed the quieter compressor. It is lighter than the reciprocating compressors. It is pulsation-free, maintains efficiencies over the operational time of the compressor. As there is no direct contact with the rotors. It uses in commercial or industrial applications and is placed into service back in the 1950s.

Within the rotary screw, housing will be the two rotors, with a clearance between them and the housing is .003 inches to .005 inches. There are two types of rotary screws compressors as well. Which are oil-free and dry rotors.

In the case of the oil-free version, the male rotary, or drive rotor, is connected through a shaft and driven by an electrical engine. The female rotor is driven by the male rotor through a thin film of oil. In the dry version, there is a set of timing gears to help achieve proper rotation.

Here is a little more about how this type of compressor operates a void created as a power applied due to the male and female rotors separating from one another. This void filled gas through a tiny inlet port. As the male rotor returns, it starts compressing the gas-filled space, pushing it to and through the discharge port.

This process then turns the screws of the compressor as the compression isolate and focus onto the housing walls. The rotary screws cool and lubricate via lubricant which injects into the housing through another small port.

Here is where you can also track quality and difference models during your price comparison. Some of the rotary-type compressors have a variable discharge value. Which seeks most efficiency by only opening and closing the respective ports based on pressure rather than static. The basic operation is simple.

When there is less air demand, the discharge value allows the air to cycle back through the inlet without begin compressed. The efficiency here is that the rotors are not subjected to a full-length operation, decreasing the power used in one respective cycle and reducing wear on the system at the same time.

3. Silent Air Compressor

- Overall Description

Silent Air (Silentaire Technology) manufactures the leading low-noise compressors in the industry. You can choose from oil-lubricated to oil-free models.

They have a large variety in several lines of compressors, from the Spectrum 2000 to their Oilless models. Also to having an outstanding line of industry-leading compressors, you will find Silentaire to be as cheap as well.

Also to retail models, they work with OEM specs for custom compressor generators. let them know your requirements and Silentaire will work to meet your needs.

Below is a brief description of the various model lines available from Silent Aire Technology.

Scorpion line. Available in both single and dual piston models. These compressors are very portable, compact, and oilless, and need no maintenance. Scorpion compressors are quiet, with sound levels over a whisper. Another great option that comes with these models is a hose that connects to any airbrush.

Operational is one click of the switch. There is also an automated off-switch that turns the compressor off when not in use. It helps reduce running time and the dangers of heat-related moisture build-up.

Super Silent line. This line is silent and can operate. Ranging from one-fifth to half Hp, each unit comes with a tank, pressure regulator with built-in moisture trap and gauge for pressure measuring, a safety value. They can be set up in an array of configurations, and there are optional 220-volt configurations in both 60Hz and 50Hz.

Sil-Air line. For increased reliability, all models in this line have one or more heavy-duty half-horsepower pumps. They also have many configurations on 220 volts. And every unit comes with a tank, built-in moisture and pressure gauges, pressure regulator, tank pressure gauge, safety valve, and a traveling handle, or wheels, for extra portability.

Val-Air line. All models in this line are top of the industry. This line considers silent. They are automatic in operation, featuring aluminum heads, and rust-resistant with the interior of the tank painted, and have an in-line coalescing filter for oil mist removal. Several models are available which include built-in electronic cooling fans for each motor.

Oilless line. This Silent Air model line offers outstanding performance and value. Including all the standard options, the Oilless line comes with an air intake filter and motor cooling fan.

Final Verdict

You will find many air compressors out there, But you need to know what type of air compressor you need. Once you find out the categories you can easily buy the best air compressor for your need.

I have tried my best to discuss the air compressor categories. If you find this article useful then please share this article. If you have anything in mind please let me know in the comment box below.

Other Popular Topics on MiniTen

[…] Best Air Compressor Categories […]