Introduction of How to Operate a Gas Powered Air Compressor

Air compressors have become a basic need of every home. It is accessible in various types, and they all services within a range of use and can work in a range of environments. Most vehicle shopkeepers use the air-compressed tank to inflate your vehicle tires.

You may also see small size portable air compressors that using in an airbrush. Some latest gas-powered air compressors use in compactors.

Exploring various gas powered compresses requires little dedication of time and power to test their needs and application.

Our comprehensive guide will focus on exploring air compressors and air compressor accessories that are worth considering.

What is a Gas Powered Air Compressor?

An electric mini air compressor is one of the most flexible devices that you can claim, particularly if you have a bigger one at your home. There is no restriction to what you can achieve with a decent air compressor. Regardless of if you need to fill tires or run huge amounts of intensity instruments.

High-pressure air compressors are more impressive. The electric partners are more compact too. Yet, how would you reveal to one extraordinary air compressor separated from another? You may inquire?

Our brief guide focuses on evaluating how these gas powered air compressors work and the benefits of having them in your house. We also look at several factors that need to consider while buying air compressors and air compressor fittings.

What are the potential uses of a gas powered air compressor?

Gas powered portable air compressors have a huge series of uses either in residential or committal places. But, there are many other intriguing uses for an air compressor. That you should think of to get the entire image of how air compressors use.

A few applications recorded beneath reveal how a gas powered air compressor can use in non-traditional ways:

- Scuba jumpers use air compressors in their plunging hardware to convey the oxygen from the tank while they’re submerged.

- Hospitals use an air compressor to convey oxygen to patients.

- Engines plan with air compressors for the warming and cooling frameworks of the vehicle.

- Paintball hardware and compressed air firearms use packed air for ammo impetus.

- Theme parks use packed air to run attractions like exciting rides, wellsprings, and energized characters.

Refrigerators and coolers use an air compressor set up to cool the air inside the unit.

How can you operate a gas powered air compressor?

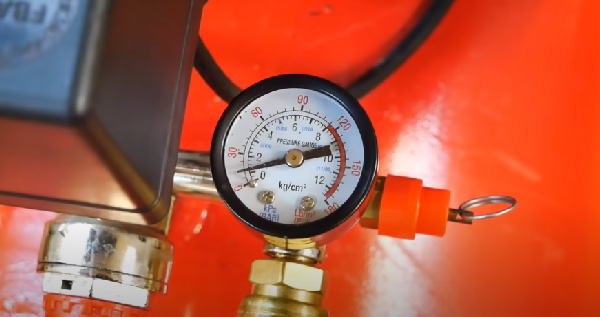

An air compressor pressure regulator joins the outlet for your air-powered gas compressors. And it highlights a movable nob and a weighted marker. It brings down the weight by lessening the air entering the controller. When you turn the handle clockwise, the spring and the valve discharge, permitting all the more high-pressure air through the yield.

At the point when the measure of compulsion expected to control your apparatus is lower than the weight in your pneumatic stress tank. A controller changes the weight for you. While the controller can’t raise the weight over what’s now in your tank. It guarantees your device gets a reliable progression of air at the right weight.

An air compressor manifold valve is a basic expansion. And it delivers compressed air to maintain a strategic distance from this issue.

Explore the list of benefits of using the best air compressor: Ultimate guide

Gas powered air compressors see as a plan workhorse in the business lane. These consider the first-hand helper at home and become an efficient tool. Compressed air is a force source that using even though many individuals neglect to acknowledge how regular it is.

Businesses and enterprises profit from the capacity to create nearby forces through air pressure. As we referenced before, compacted air can be costly to deliver. But, it reduces the expenses of creation from many points of view. It’s an important component of pretty much every assembling and modern setting.

Conventional benefits of using a gas powered air compressor

The air compressor works well and feels lighter. They are tough, particularly when used continuously and in harsh and grimy conditions. Their use brings about an expansion in profitability and productivity from speedier apparatus speed and client strain that is incredibly diminished or killed by and large.

The extreme applications that are regular in steel factories and foundries are not inviting for electric-controlled instruments. The high temperatures and grimy environmental factors are the ideal settings for continuous electrical over-burdening and hardware breaking down.

Air apparatuses need some intermittent upkeep, yet they need less than their electric air compressor tools.

Another great component of the compressed air conditioner tank is that it is very well put away to help variances usage. Not agonizing over spikes in power use can trip circuits, and damaging gear is the main concern of any creation line.

An air compressor can install to fulfill the needs of any consistent and fluctuating use. With the correct framework, you get the essential weight and capacity tank to give solid and steady energy.

Heat recovery benefits that can increase the working efficiency

To neutralize the high cost of creating air compressor frameworks can recoup the warmth delivered from the pressure to be used somewhere else in an office. This warmth can use for alternate applications like space warming, warming cycle water, oils, or different liquids used to create or convey to the plant storage space heated water for showers.

One of the least demanding warm air compressor air filters to execute is space warming. Which can recoup up to 94 percent of an air compressor framework’s info power. You can see many ventures could make the significant expense of delivering a nearby force with air pressure. An easy-open door for sparing in different zones.

Guidelines to determine the best gas powered air compressor

There are a few parts to examine while picking the best air compressor for residential or commercial use. You should search to locate the most suitable compressor for your particular reason. Check these highlights before you decide to buy an air compressor.

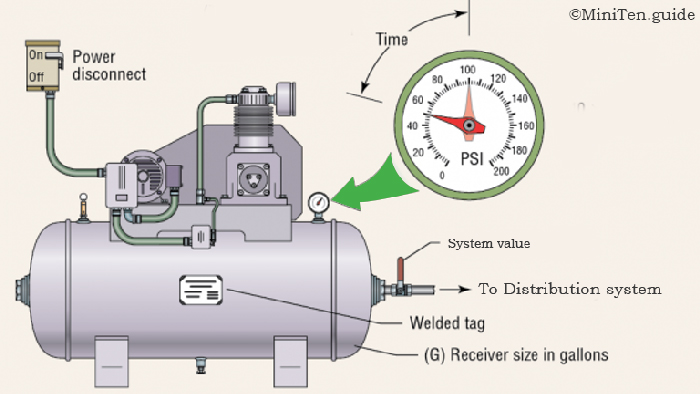

- Tank Size

The tank size of air compressors manages how long the pneumatic tool can run before the compressor betrays. The tank volume measures in gallons, going from 1 gallon to 80 gallons. Little tank sizes will be enough if you want to use air devices for a specific time.

- Force Source: Electric or Gas powered: Which one to choose?

Air compressors can be used either by power or gas. We should view how this influences the compressor qualities.

- Electric compressors

Electric compressors contrast with gas-controlled compressors. They are expensive but rather more helpful, especially if the site has an electrical plug. These compressors are very adaptable to styles and estimates and are lightweight.

They don’t emanate any smoke, subsequently ideal for indoor uses, for example, fixes, trimming, and finish work. Also, they run on standard family voltage, i.e., 110-120 V. Be that as it may, it might change and reach up to 220-240 V, contingent upon the pull.

One thing to remember is that driving with a generator may hamper the exhibition of the air compressor drain valve over a long period.

- Gas powered air compressors

As you most likely know, gas powered air compressors use gas for power, When electrical stopping isn’t an alternative. Moreover, they are likewise appropriate for inaccessible use with an extra line. These compressors can work persistently, making them ideal for medium to rock-solid mechanical applications.

They are weighty and massive. As a disadvantage, these compressors create boisterous exhaust vapor. They are not good for indoor use.

- Oil-free or lubricated air compressors

Latest lubricated air compressors expect oil to grease up the cylinder chamber or screws to forestall unreasonable rubbing, wear, and overheating. This sort of compressor needs an oil change and channel change some time to stay away from mistimed disappointment.

Checking and upkeep are required so the oil doesn’t leak through and taint the air. These compressors are on the heavier and costlier side. You need to note that oil-greased-up air compressors last longer contrasted with those without oil ones.

They are less loud on account of being very much greased up. Having lubricated air compressors can avoid the problem of air compressor troubleshooting.

On the other way, oil-free compressors are pre-greased up with materials, for example, Teflon, which fills in as a perpetual ointment. The odds of air tainting are impossible. As there are lesser parts, these compressors are generally more modest, lighter, and cheap. In this manner, without oil, compressors will be ideal for your home use or if versatility is an inclination to you.

There are a couple of disservices related to this sort of compressor. The covered lubricants in a compressor may work for a long time, and the compressor can run more blazing and stronger. These compressors may not keep going insofar as compared to the lubricant ones.

- Air compressor portability

The feature can be an important factor to consider while purchasing a gas powered air compressor. In light of your expected application, you may pick a versatile or a fixed compressor.

- Versatile compressors: These are of little limit and light to convey to a site or stowed away. If you are a property holder and contractual worker, you may like a flapjack, twin-stack, or sausage compressor. They are useful for home or pastime use during crises, such as a penetrated tire or even building locales.

- Fixed compressors: These compressors are very ground-breaking with enormous limits and heavyweight. They are not good to carry here and there. These can be used in carports, workshops, or enterprises. Also, these compressors are more costly than portable ones. Also, wheeled compressors fall someplace in the center. These are not as lightweight to hand-convey as fixed models.

- The compressor noise level

The gas powered air compressor has a noise level. The level can be an issue for some compressors, without oil and versatile ones. You would like a peaceful activity, particularly for home use or indoor applications. Also, as should be obvious, it is a partner with many different factors, for example, oil, the number of moving parts, cost, and so on.

There are some cutting-edge innovations out there to decrease the commotion level, e.g., double cylinder activity. Plus, you can likewise use walled-in areas or sound-dampeners to many the level of sound in your living areas.

- Air Treatments

Fitting air treatment is pivotal for the exhibition and toughness of an air compressor. Air treatment parts incorporate air dryers, air channels, and so on. The principal objectives of air treatment are:

- Removing dampness and pollutants

- Refining toxins and forestalling developments

- Filtering or isolating oil

You have to make sure that the air conveyed is spotless and dry. Wet, grimy air can cause crumble the compressor capacities and harm it. In like manner, an absence of an oil separator will represent a well-being peril if the atomized oil pollutes the air you relax. Along these lines, try to choose the best possible air treatment tools for your compressor.

- Installation tools

While little compressors for private use are generally simpler to install. There are any key air compressor attachments you have to recollect, for example,

- Install the compressor in a spotless, dry, and very much ventilated territory.

- Keep abundant space between the compressor and your divider.

- Hose lengths and connection fittings ought to be suitable.

- The voltage ought to be agreeable.

The establishment of fixed or mechanical evaluation air compressors can be dubious. So you may need help from affirmed experts.

- Basic Accessories

Air compressors and units are essential to improve the exhibition of your air compressor. Some fundamental extras incorporate controllers, air hoses, checks, apparatus connections, and so on. Moreover, lubricators, extra tanks, substitution siphons, and electrical lines are essential for specific kinds of compressors. So, pick great quality accomplices to limit the requirement for support.

- Air compressor tools

A definitive motivation behind most compressors is to control your air devices. There are different pneumatic devices, for example, ratchets, air sleds, sprayers, and processors. Each air compressor tool has a particular prerequisite for wind stream rate and weight.

How can you add oil to your air conditioning compressor?

The gas powered air compressor has an air compressor auto drain responsible for its mainstream working. It implies that these machines need an air compressor oil change like a motor would. Changing your air compressor’s oil is significant, not only to its item life but also to the machine’s effectiveness. It will permit the permit to stream all the from the siphon.

- Position a container under the siphon end of the unit.

- Remove the oil channel plug. Permit oil to gather in the dish

- Replace the compressor oil channel plug.

- Now put the oil fill cap or halt on the siphon. Gradually fill siphon to full level as demonstrated on dipstick or sight glass utilizing a top-notch air compressor oil. We suggest Mobil 1 10w-30 manufactured engine oil, which will work great.

- Replace a breather/fill cap on the siphon.

Frequently Asked Question and Answers

- What do you mean by the gas powered air compressor?

As the name infers, this kind of compressor is fuel on gas instead of power or diesel, and there are many advantages to working with them. Dissimilar to the blowers’ electric-fueled models, a gas air blower should not connect to a force source.

- What is the operation of these compressors?

All air blowers comprise an engine, a cylinder, and a capacity tank. More modest blowers commonly can store between one gallon and five gallons of packed air. It will refine when the cylinder drives air into the tank more than once, compelling a huge cubic volume of air into the more modest, kept space.

- How regularly do you have to place oil or lubricant in air compressors?

The period will rely upon the assortment of oil blowers you own. Based upon use, responding air blowers need new oil at regular intervals. Or somewhere in the vicinity while turning screw blowers need new oil at the 1,000-hour mark. It’s essential to assess the oil channel in your compressor.

- What’s the exact size of air compressor you need for your home?

Rather than evaluating an air compressor’s ability by its size, you need to look at its capacity to work. So you need to look at how much air it conveys, which is measured in Cubic Feet Per Minute (CFM). As a rule, gas powered compressors implied for driving instruments fall in the 30 to 140 CFM range.

- What are the preferred uses of these compressors?

Air compressors have many applications, including providing high-compel clean air to fill gas chambers. And providing moderate-pressure clean air to a lowered surface provided jumpers.

Final Verdict

As we all know, a gas powered air compressor is a gadget that converts power into potential energy put away as pressurized air or compacted air. Because of the explanation, a conservative and little estimated air compressor can fit on any side of your carport or workshop. When you are putting it away.

So need to take the best one for having better outcomes. In our guide, you can focus on several factors that need to consider while choosing an air compressor for your home.

Other Popular Topics of MiniTen

Visitor Rating: 5 Stars

[…] What is Gas Powered Air Compressor and How does It Works? […]